Everything about this repair was interesting! The client contacted me after a referral from Gryphon Strings up in Palo Alto, one of the best repair operations on the West coast. The patient was nearly identical to other Howe-Orme instruments I’d seen online and in museums, but unlike every other one I’d ever seen, this one had not one but two sound holes, and an extra brace running between them from transverse braces above and below the holes. No label inside, and no serial number stamped on the end of the head stock. A prototype? A one-off made by a factory employee? Who knows! The key thing was that the client wanted to revive it to playable condition – a tall order due to the extremely light construction and brittle condition, not to mention the various cracks and other problems.

Among the obvious issues:

- Cracked neck heel, and badly needed neck reset – the end of the fretboard, which was supposed to be floating over the top, had been pressing against the top for many years due to string tension.

- Two cracks in the top on either side of the scratch plate, probably due to shrinkage which needed repair and cleats.

- Multiple back and side cracks, missing pearl fingerboard dots.

The top cracks were cleaned and filled with a spruce splinter, tightly fit to the crack dimensions. Two small cleats were then glued underneath with cross-grain orientation using fish glue.

The back brace visible beneath the sound holes was split along the grain and was re glued, also with fish glue. Longitudinal back cracks were glued tight with thin cyanoacrylate (aka “super glue”) and clamped until set.

On to the neck reset. My original strategy was to remove the entire fret board, but after assessing it’s brittleness I decided to saw off only the tongue at the neck join. I use a small non-steam travel iron for this, and it came off quickly.

As you can see in the above image, I had to saw off the base of the tongue since there was a dowel through the whole neck top to bottom. Although the heel itself was cracked, the dowel held the parts together. I drilled this dowel out, clamped and glued the heel, and inserted a new hardwood dowel. The small holes in on either side of the dowel are holes I drilled for a heat stick, which failed to loosen the joint.

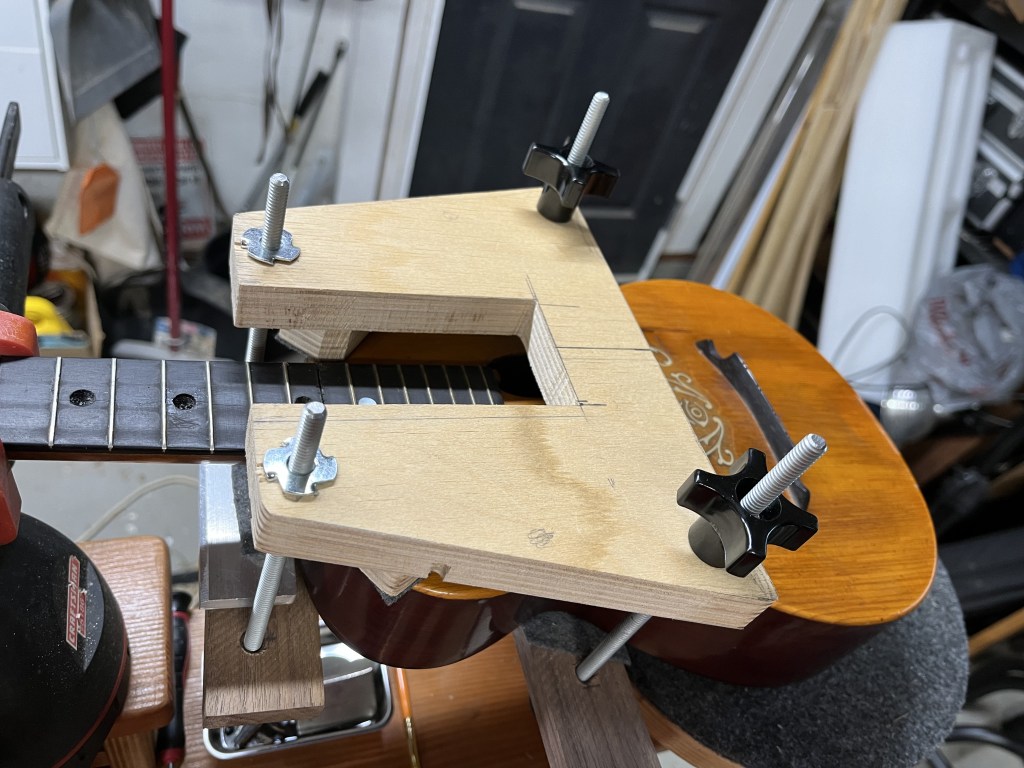

I constructed a miniature neck removal jig from scrap wood and all-thread rod, and then heated the joint with a hair dryer until it released.

After taking some measurements through the sound holes, I realized the neck block was barely 3/8″ thick inside the body. I didn’t think this was going to be structurally sound in the long run, and after discussion with the client, decided to glue a block inside on the neck block to thicken it, and put in machine screws and inserts rather than gluing the neck back into the pocket.

I then made a new tongue (the original had split during removal) and reattached the floating section of the fret board, replaced the frets I had removed during the detachment process, added a shim in the pocket for correct neck angle, and bolted the neck back on.

The screws are reached via a 1/4″ hole bored in the tailblock which is covered by the tailpiece.

I then inlaid new pearl dots, cleaned and oiled the board, leveled and dressed the frets, and made a new bridge to set string height. The client supplied new GHS ultra-light strings (9-32) and after tuning up, sounded pretty darn good! A unique example from Howe-Orme.